Following on from our previous generator replacement project we were asked by the vessel managers Bernard Schulte Ship Management to investigate the feasibility of replacing the valve control system.

The existing system was PC based, comprising 7 valve outstations distributed around the vessel with RS485 serial communication between the control & monitoring PCs in the ECR & CCR and the valve outstations.

The control and monitoring PCs and outstation electronics were defective and the valves were having to be operated and monitored manually, causing considerable work for the crew.

The existing manufacturers had previously been contacted and informed the owners that the system was obsolete and must be replaced and also that their replacement system would not work with the existing cabling.

For an LPG vessel this is a major problem as the work and cost required to replace the cabling to the valve outstations would have been enormous due to the location of the hotwork required.

For an LPG vessel this is a major problem as the work and cost required to replace the cabling to the valve outstations would have been enormous due to the location of the hotwork required.

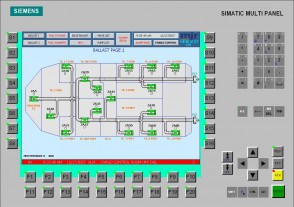

We proposed a PLC based solution that would work with the existing cabling and provide all of the functionality of the existing system but with high levels of reliability and redundancy.

Once again we were faced with having to complete the retrofit with the vessel in service – our speciality!

We developed a highly modular solution with replacement outstation internal components that could be simply mounted in place of the existing electronics, even down to having the same plugs & sockets.

This ‘plug in’ solution worked incredibly well and the whole system was replaced and comissioned in several days during a trip between European ports.

The cost savings were massive and the system continues to work well with no service calls since comissioning.